Lefats'eng la tlhahiso ea indasteri le ts'ebetso ea tšepe, ho nepahala le ho sebetsa hantle ke tsa bohlokoa. E 'ngoe ea lisebelisoa tsa bohlokoa tse kenyelletsang litšoaneleho tsena ke hydraulic shear. Li-shear tsa Hydraulic ke mechini e matla ea ho itšeha e sebelisang khatello ea haeteroliki ho cheka thepa e fapaneng hantle, haholo litšepe. Ka bokhoni ba bona ba ho sebetsana le mesebetsi e mengata e fapaneng le ho hlahisa likheo tse hloekileng, tse nepahetseng, li-shears tsa hydraulic li fetohile thepa ea bohlokoa liindastering tse fapaneng.

Mechanics ka morao ho Likhetla tsa Hydraulic

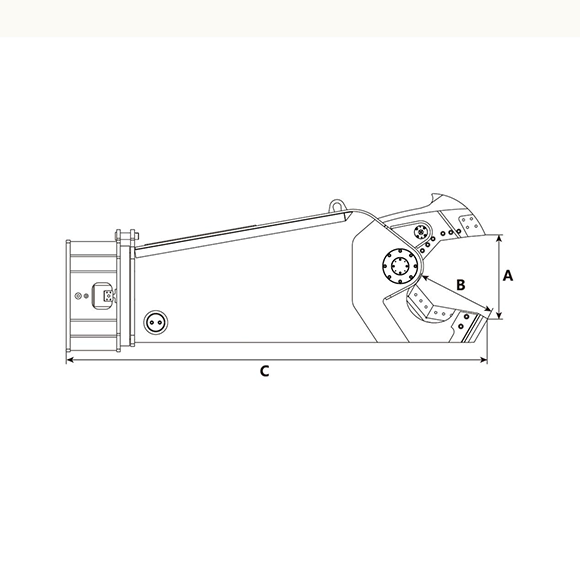

Li-shears tsa Hydraulic li sebetsa ho latela molao-motheo oa mochini oa mokelikeli, li sebelisa khatello ea haeteroliki ho hlahisa matla a hlokahalang bakeng sa ho seha. Likarolo tsa bohlokoa tsa shear ea hydraulic li kenyelletsa letamo la metsi a hydraulic, pompo ea hydraulic, li-valve tsa taolo, lehare la ho itšeha kapa li-blades, le foreimi ho tšehetsa sebopeho sohle.

Ts'ebetso e qala ka pompo ea hydraulic e hatellang mokelikeli oa hydraulic, hangata oli. Joale mokelikeli ona o hatelitsoeng o tsamaisoa ka li-valve tsa taolo tse laolang ho phalla le khatello. Li-valve tsena li sebelisoa ke mochine oa mochine, ea khonang ho laola mokhoa oa ho itšeha ka mokhoa o nepahetseng.

Mokelikeli o hatelloang oa haeteroliki o fetisetsoa ho li-cylinders tsa haeteroliki, tseo hape li hlahisang matla a matla a tsamaisang lehare (ma)hare ho ea tlase holim'a thepa e lokelang ho khaoloa. Khatello e kholo e sebelisoang ke li-cylinders tsa hydraulic e lumella ho kuta ka mokhoa o nepahetseng ka har'a thepa, ho siea sehiloeng se hloekileng le se nepahetseng. Li-valve tsa taolo li boetse li lumella opareitara hore a fetole sebaka sa ho itšeha le ho hlakola lehare, ho nolofalletsa ho itlhophisa ho latela thepa le botenya bo itseng.

Lisebelisoa tsa Hydraulic Shears

Li-shear tsa Hydraulic li fumana lits'ebetso ho pholletsa le liindasteri tse fapaneng ka lebaka la ho feto-fetoha ha tsona le bokhoni ba ho sebetsana le lisebelisoa tse fapaneng. Lisebelisoa tse ling tse tloaelehileng li kenyelletsa:

1. Metal Fabrication: Li-shears tsa Hydraulic li sebelisoa haholo mabenkeleng a entsoeng ka tšepe ho seha lisebelisoa tsa tšepe le lipoleiti. Ba khona ho sebetsana le lisebelisoa tse kang tšepe, aluminium le tšepe e sa hloekang habonolo, ba li etsa lisebelisoa tsa bohlokoa bakeng sa ho theha likarolo tse sebelisoang mohahong, likoloi, sefofane le liindasteri tse ling.

2. Kaho ea Likepe: Lirapeng tsa likepe, li-shears tsa hydraulic li sebelisoa ho khaola le ho etsa lipoleiti tsa tšepe bakeng sa likepe tsa likepe, li-decks le likarolo tse ling tsa sebopeho. Bokhoni ba bona ba ho hlahisa likhahla tse nepahetseng ke tsa bohlokoa ho boloka botšepehi ba sebopeho sa likepe.

3. Ts'ebetso ea Scrap: Li-shears tsa Hydraulic li phetha karolo ea bohlokoa lits'ebetsong tsa ho tsosolosa le ho lokisa lisebelisoa. Li sebelisetsoa ho seha le ho sebetsa lintho tse kholo tsa tšepe joalo ka likoloi, lisebelisoa le mechini hore e be likotoana tse laolehang bakeng sa ho sebelisoa hape.

4. Ho senya: Ka indasteri ea ho senya, li-shears tsa hydraulic li kenngoa holim'a li-epollo 'me li sebelisetsoa ho khaola ka konkreite e matlafalitsoeng, maballo a tšepe le lisebelisoa tse ling nakong ea ts'ebetso ea ho senya.

5.Manufacturing: Li-shears tsa Hydraulic ke karolo ea ho etsa lihlahisoa tse fapa-fapaneng, ho kenyelletsa le lik'habote tsa tšepe, li-enclosures, le lisebelisoa, moo ho khaola ka mokhoa o nepahetseng ho hlokahalang bakeng sa ho netefatsa hore ho lekana hantle le ho sebetsa hantle.

Melemo ea Hydraulic Shears

1.Precision: Li-shears tsa Hydraulic li fana ka mokhoa o ikhethang oa ho itšeha, o fellang ka ho khaola ho hloekileng le ho nepahetseng esita le ka libopeho le mekhoa e rarahaneng.

2. Matla a Matla a ho Seha: Sesebelisoa sa hydraulic se fana ka matla a phahameng a ho itšeha, a nolofalletsang ho kuta habonolo lisebelisoa tse teteaneng le tse thata.

3. Mefuta-futa: Li-shears tsa Hydraulic li ka khaola mefuta e mengata ea lisebelisoa, ho tloha maqepheng a masesaane ho ea ho lipoleiti tse boima, ho etsa hore li tšoanelehe bakeng sa lisebelisoa tse fapaneng.

4. Katleho: Likere tsena li sebetsa hantle ebile li boloka nako, li lumella basebelisi ho qeta mesebetsi ea ho itšeha kapele le ka boiteko bo fokolang.

5.Minimal Deformation: Ketso e nepahetseng ea ho itšeha ea li-hydraulic shears e fokotsa ho senyeha ha thepa le litšila, ho fella ka tšebeliso e phahameng ea thepa.

Nako ea poso: Sep-21-2023