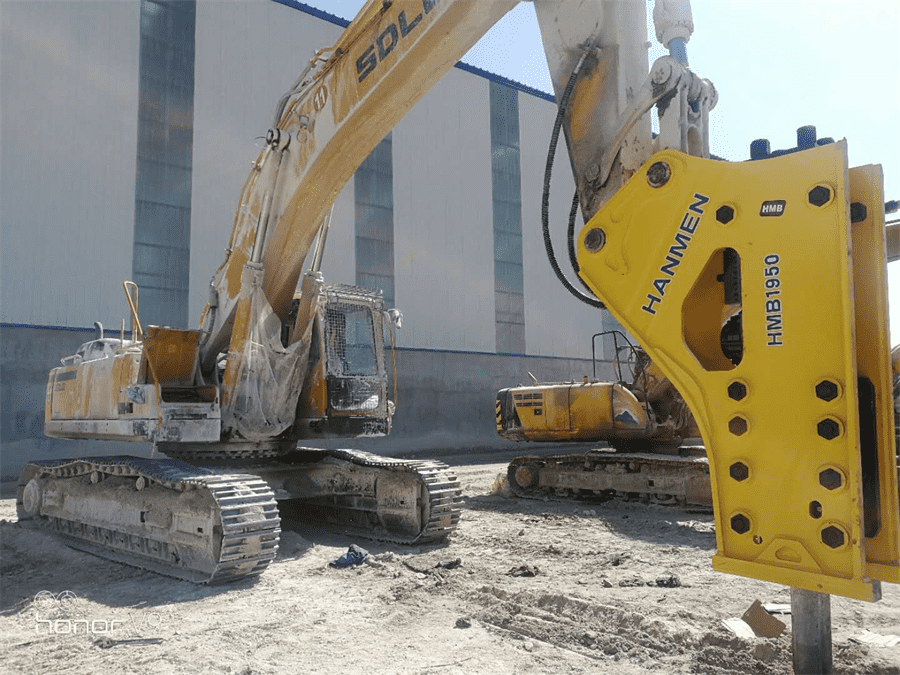

Hydraulic breakers are becoming more and more common in various engineering projects such as urban construction, with high crushing efficiency, low maintenance costs, and higher economic benefits, and are loved by more and more people.

content:

1. The power source of hydraulic breaker

2. How to choose the right hydraulic breaker for your excavator?

● The weight of the excavator

● According to the working pressure of hydraulic breaker

● According to the structure of hydraulic breaker

3. Contact us

The power source of the hydraulic breaker is the pressure provided by the excavator, loader or pumping station, so that it can reach the maximum working intensity during crushing and effectively break the object. With the expansion of the hydraulic breaker market, many customers do not know Which manufacturer should I choose? What is to judge the quality of a hydraulic breaker? Is it suitable for your needs?

When you have a plan to buy a hydraulic breaker/hydraulic hammer:

should consider the following aspects:

1) The weight of the excavator

The exact weight of the excavator must be understood. Only by knowing the weight of your excavator can you better match the hydraulic breaker.

When the weight of the excavator> the weight of the hydraulic breaker:the hydraulic breaker and the excavator will not be able to perform 100% of their working capacity. When the weight of the excavator < the weight of the hydraulic breaker: the excavator will fall due to the excessive weight of the breaker when the arm is extended, accelerating the damage of both.

|

HMB350 |

HMB400 |

HMB450 |

HMB530 |

HMB600 |

HMB680 |

||

|

For Excavator Weight(Ton) |

0.6-1 |

0.8-1.2 |

1-2 |

2-5 |

4-6 |

5-7 |

|

|

Operating Weight(Kg) |

Side Type |

82 |

90 |

100 |

130 |

240 |

250 |

|

Top Type |

90 |

110 |

122 |

150 |

280 |

300 |

|

|

Silenced Type |

98 |

130 |

150 |

190 |

320 |

340 |

|

|

Backhoe type |

|

|

110 |

130 |

280 |

300 |

|

|

Skid steer loader type |

|

|

235 |

283 |

308 |

336 |

|

|

Working Flow(L/Min) |

10-30 |

15-30 |

20-40 |

25-45 |

30-60 |

36-60 |

|

|

Working Pressure(Bar) |

80-110 |

90-120 |

90-120 |

90-120 |

100-130 |

110-140 |

|

|

Hose Diameter(Inch) |

1/2 |

1/2 |

1/2 |

1/2 |

1/2 |

1/2 |

|

|

Tool Diameter(mm) |

35 |

40 |

45 |

53 |

60 |

68 |

|

2) Working flow of hydraulic breaker

Different manufacturers of hydraulic breakers have different specifications and different working flow rates. The working flow rate of the hydraulic breaker needs to be equal to the output flow rate of the excavator. If the output flow rate is greater than the required flow rate of the hydraulic breaker, the hydraulic system will generate excess heat. The temperature of the system is too high and the service life is reduced.

3) Structure of hydraulic breaker

There are three common types of hydraulic breakers: side type, top type and box type silence type

The side type hydraulic breaker is mainly to reduce the total length,The same point as the top hydraulic breaker is that the noise is greater than that of the box-type hydraulic breaker. There is no closed shell to protect the body. Usually there are only two splints to protect both sides of the breaker. Easily damaged.

The box-type hydraulic breaker has a closed shell, which can perfectly protect the body of the hydraulic breaker, is easy to maintain, has low noise, is more environmentally friendly, and has less vibration. It solves the problem of loosening of the shell of the hydraulic breaker. Box-type hydraulic breakers are loved by more people.

Why choose us ?

Yantai Jiwei controls the quality of products from the source, adopts high-quality raw materials, and adopts mature heat treatment technology to ensure that the wear on the impact surface of the piston is minimized and the service life of the piston is maximized. Piston production adopts precision tolerance control to ensure that the piston and cylinder can be replaced with a single product, reducing maintenance costs.

With the improvement of hydraulic system working parameters and the strengthening of environmental protection awareness, the shell of the breaker has put forward higher and higher requirements for its sealing system. The NOK brand oil seal ensures that our hydraulic breakers have low (zero) leakage, low friction and wear and a longer service life.

Post time: Aug-12-2021