With the continuous extension of excavator attachments, excavators have also been given different functions. The original definition of excavator is inseparable from the bucket. It is very important to have a good bucket. With the change of the construction scene, the excavation object may also be hard or soft, and various forms of buckets have appeared. The significance of this article is to help you choose the most suitable bucket from a large number of buckets.

With the continuous extension of excavator attachments, excavators have also been given different functions. The original definition of excavator is inseparable from the bucket. It is very important to have a good bucket. With the change of the construction scene, the excavation object may also be hard or soft, and various forms of buckets have appeared. The significance of this article is to help you choose the most suitable bucket from a large number of buckets.

1.Definition of excavator bucket

2.What you need to know about excavator buckets

2.1What are the different types?

2.2Considering the required load capacity of the bucket in the actual application environment

2.3How to maintain the bucket?

3.Small suggestions

4.Contact our experts

Definition of excavator bucket

The excavator bucket is designed to be connected to the front of the excavator and used as an extension of its arm. Compared to trying them by hand alone, they allow you to dig deeper, lift more weight, and shovel out material more efficiently.

In the construction industry, excavator buckets are essential for effective work. They help to dig, load and move large materials and objects on various terrains.

What you need to know about excavator buckets

There are a few things that you need to learn when buying bucketfor your excavator .Here are a few:

Types of excavator buckets

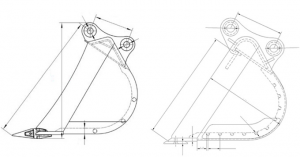

- Standard bucket

The standard bucket is a standard bucket that is relatively common in small and medium-sized excavators. It uses a standard plate thickness, and there is no obvious reinforcement process on the bucket body.

The characteristics are: large bucket capacity, large bucket mouth area, high working efficiency of the excavator, and low production cost. Suitable for lighter working environments such as general clay excavation and sand, soil, gravel loading, etc.

- Strengthen bucket

The reinforced bucket is a bucket that uses high-strength wear-resistant steel materials to reinforce the high-stress and wear-prone parts on the original basis of the standard bucket.

It has all the advantages of the standard bucket and greatly improves the strength and wear resistance, and the service life is greatly extended. It is suitable for heavy-duty operations such as excavation of hard soil, softer rocks, gravel, gravel loading and so on.

- Rock bucket

The rock digging bucket adopts thickened plates as a whole, with reinforcement plates added at the bottom, side guard plates, protective plates installed, and high-strength bucket tooth seats.

It is suitable for heavy operation environments such as loading of rocks, sub-hard stones, weathered stones, hard stones, and blasted ores. It is widely used in harsh working conditions such as ore mining.

- Tilt bucket

The operation can be carried out without changing the position of the excavator, and the precise operation that can not be completed by ordinary buckets can be easily completed.

It is suitable for cleaning slopes, leveling and restoring planes, and dredging rivers and ditches. It is not suitable for heavy work environment such as excavation of hard soil and rocky soil.

The main composition of the structural material of the bucket

Steel and aluminum are the main choices for bucket construction materials. Aluminum drums are generally lighter in weight and easier to handle with machines, but they also tend to be more costly. Steel buckets are stronger, better at handling high-pressure loads, and last longer than aluminum buckets.

Need to consider the required load capacity of the bucket in the actual application environment

Need to consider the required load capacity of the bucket in the actual application environment

In the excavation operation, the bucket is the most loaded part and is a vulnerable part. Especially in the stone work, the bucket wears very fast. Therefore, when purchasing an excavator bucket, first confirm whether the bucket you choose meets the load carrying capacity of your project. For example, if you use it mainly in a soil environment, you can use a smaller bucket load capacity.

How to maintain the bucket?

1. Don’t use a bucket to pry open objects

2. Avoid using the bucket to drop and impact the rock work. Using this method of work will reduce the bucket life by about a quarter.

3. Do not revolve and hit the object, because when the bucket collides with the rock, the bucket, boom, working device and frame will generate excessive load, and the rotation force when moving large objects will also produce too much Large load greatly reduces the service life of the excavator.

Little advice

When you compare different brands of buckets, you can’t blindly pursue low prices, but when you get the price, add the cost of installation and maintenance to the price of the bucket. In this way, you can pay for your excavator. Choose a better bucket that runs harmoniously for a longer period of time instead of a bad bucket that requires several repairs.

The various types, brands, and prices of excavator buckets often make it difficult for purchasers to make the right decision. As long as you compare this article and consider the factors mentioned, it will definitely help you find the most suitable for your excavation. Bucket of the machine.

1.Definition of excavator bucket

2.What you need to know about excavator buckets

2.1What are the different types?

2.2Considering the required load capacity of the bucket in the actual application environment

2.3How to maintain the bucket?

3.Small suggestions

4.Contact our experts

Post time: Aug-30-2021