The chisel is wearing part of a hydraulic hammer breaker. The tip of chisel would be worn during the working process, it is mainly used in ore, roadbed, concrete, ship, slag, etc working site. It is necessary to pay attention to the daily maintenance,So the correct selection and use of chisel is the key to hydraulic hammer breaker loss reduction.

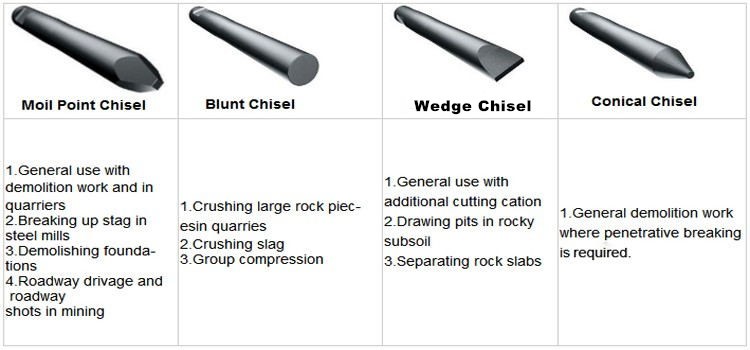

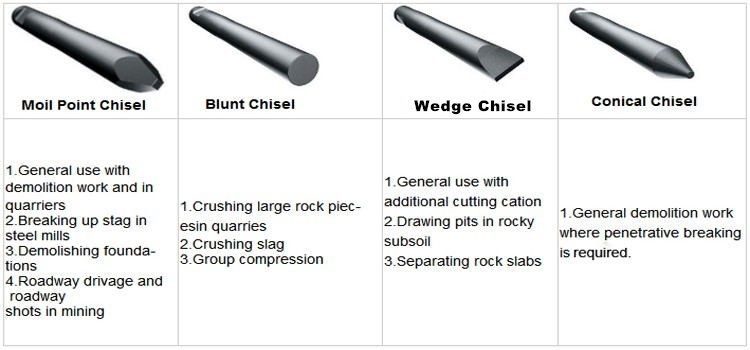

Selection Guide of chisel

1. Moil point chisel: suitable for hard stone, extra hard rock, and reinforced concrete excavation and broken.

2 .Blunt chisel: mainly used in breaking medium-hard rocks or small cracked stones to make them smaller.

3. Wedge chisel: suitable for soft and neutral layer rocks excavation, concrete breaking, and excavation of ditches.

4. Conical chisel: mainly used in breaking tough rocks, such as granite, and quartzite in quarry, also used for breaking heavy and thickened concrete.

pay attention to checking the chisel and chisel pin every 100-150 hours.so How to replacement of chisel?

Instructions for chisel operation:

1. The suitable downward force can improve the efficiency of the hydraulic hammer breaker.

2. The position of the hammer breaker adjustment – when the hammer breaker cannot break the rock, it should be moved to a new hitting point.

3. The breaking operation shall not be operated continuously at the same position. The the temperature of chisel would rise when breaking at the same position for a long time. The chisel hardness would be reduced to damage the tip of chisel, thereby the operation efficiency cut down.

4. Do not use the chisel as a lever to pry rocks.

5. Please put down the excavator arm to a safe state when stopping operation. Don’t leave the excavator when the engine is started. Please ensure all brake and locking devices ineffective state.

Post time: Jun-18-2022