1. Start from checking lubrication

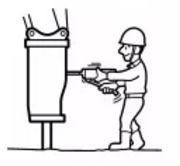

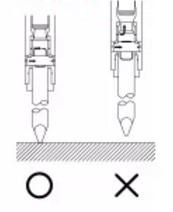

When the hydraulic breaker starts crushing work or the continuous working time has exceeded 2-3 hours, the frequency of lubrication is four times a day. Note that when injecting butter into the hydraulic rock breaker, the breaker should be placed vertically and the chisel should be compacted and not suspended. The advantage of this is to prevent the butter from flowing into the hydraulic system of the breaker. The butter should be injected in a proper amount. If it is injected too much, it will stick to the piston, and it will also cause the butter to enter the hydraulic system during immediate operation.

Tips: Check that the hydraulic breaker you have has several grease nipples. There are two grease nipples. Each grease nipple needs to be hit 5 to 10 times, and only one grease nipple needs to be hit 10 to 15 times. Note that most breakers also have an automatic lubrication system port.

2. Check the bolts and screws

When starting the crushing work, check whether the through-body bolts are cracked. Before unscrewing the through-body bolts, the nitrogen (N2) in the upper body should be completely released, otherwise the upper body will eject when the through-body bolts are removed, which will cause serious consequences. When installing the full-body bolts after the inspection, the bolts

should be tightened in the diagonal direction, instead of tightening one bolt in place at once. In addition, after hydraulic Jack hammer works, check the screw and nut condition of each part, and tighten it in time if it is loose.

3. Check if the nitrogen reserve is sufficient

In the case of an accumulator in the structure of the hydraulic breaker, insufficient nitrogen storage will cause weak blows, and it will also easily lead to damage to the leather cup, and maintenance is also troublesome. Therefore, before the demolition breaker is working, you need to use a nitrogen meter to measure the amount of nitrogen and make a proper nitrogen reserve. Newly installed hydraulic breakers and repaired hydraulic breakers must be refilled with nitrogen when they are activated.

The Martillo hidraulico is inspected every 8 hours of work. The inspection items are:

•Whether the bolts are loose, whether there is oil leakage, whether there are damaged parts, missing parts and worn parts

bolts loose

oil leakage

• Check the working condition of the hydraulic breaker

• Check whether the overall condition of the hydraulic system is normal

• Check whether the bolts are loose or missing

• Check the condition of hydraulic lines and hydraulic joints

• Check whether the drill rod and lower bushing are worn

• Before operating the breaker, please replace damaged or worn parts.

Have you mastered the items that need to be checked for each time period and state of the hydraulic breaker? Only by doing the daily inspection items every time, the life of your breaker will be longer and help you get better income.

Post time: Mar-18-2021